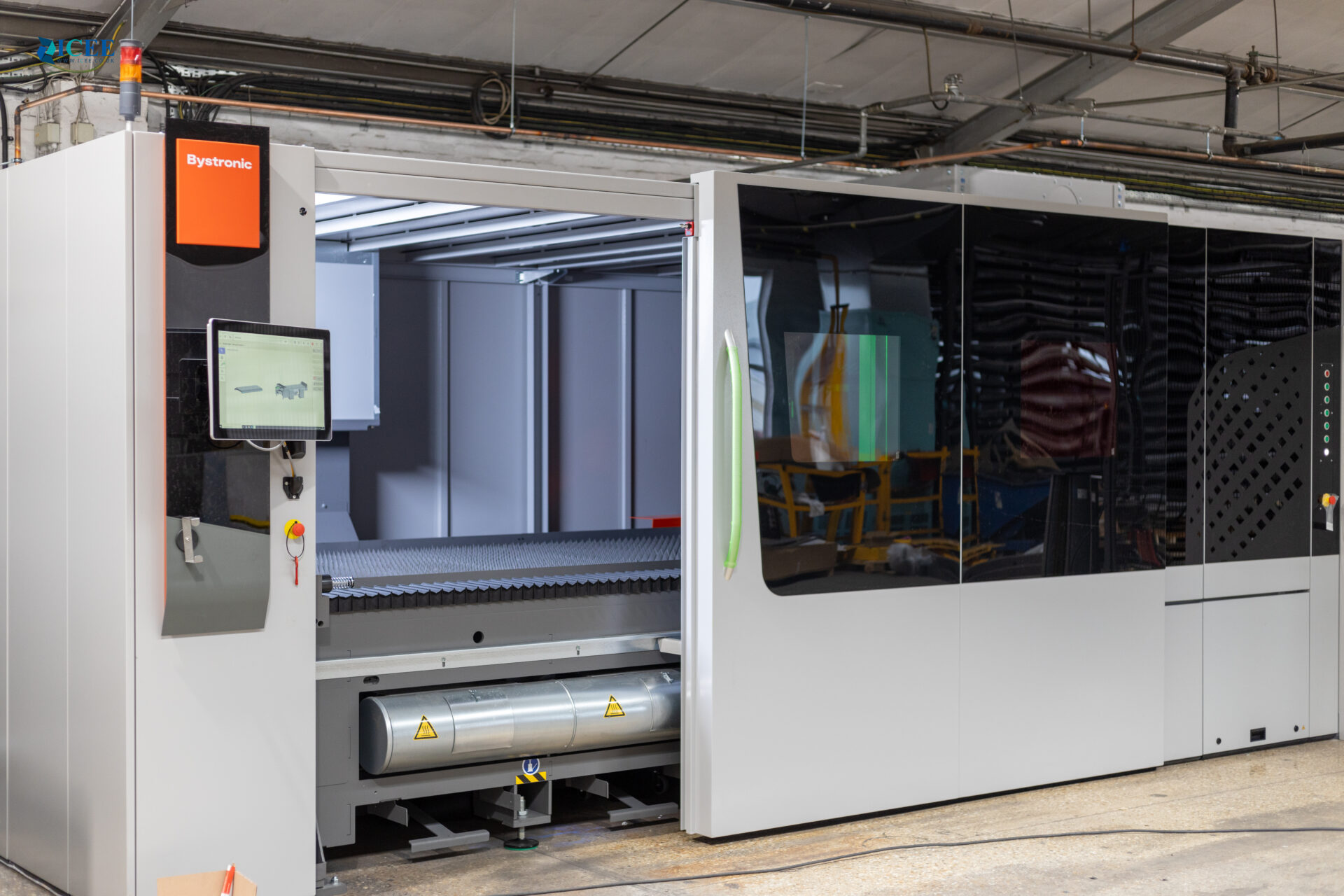

ICEE are today thrilled to announce our investment in a new Bystronic 6KW ByCut Star Fibre Laser, set to develop our advanced Profile Cutting Service. The new state-of-the-art technology represents a significant leap forward in our manufacturing capabilities, offering enhanced speed, precision and versatility, while keeping ICEE at the forefront of the sheet metal manufacturing industry.

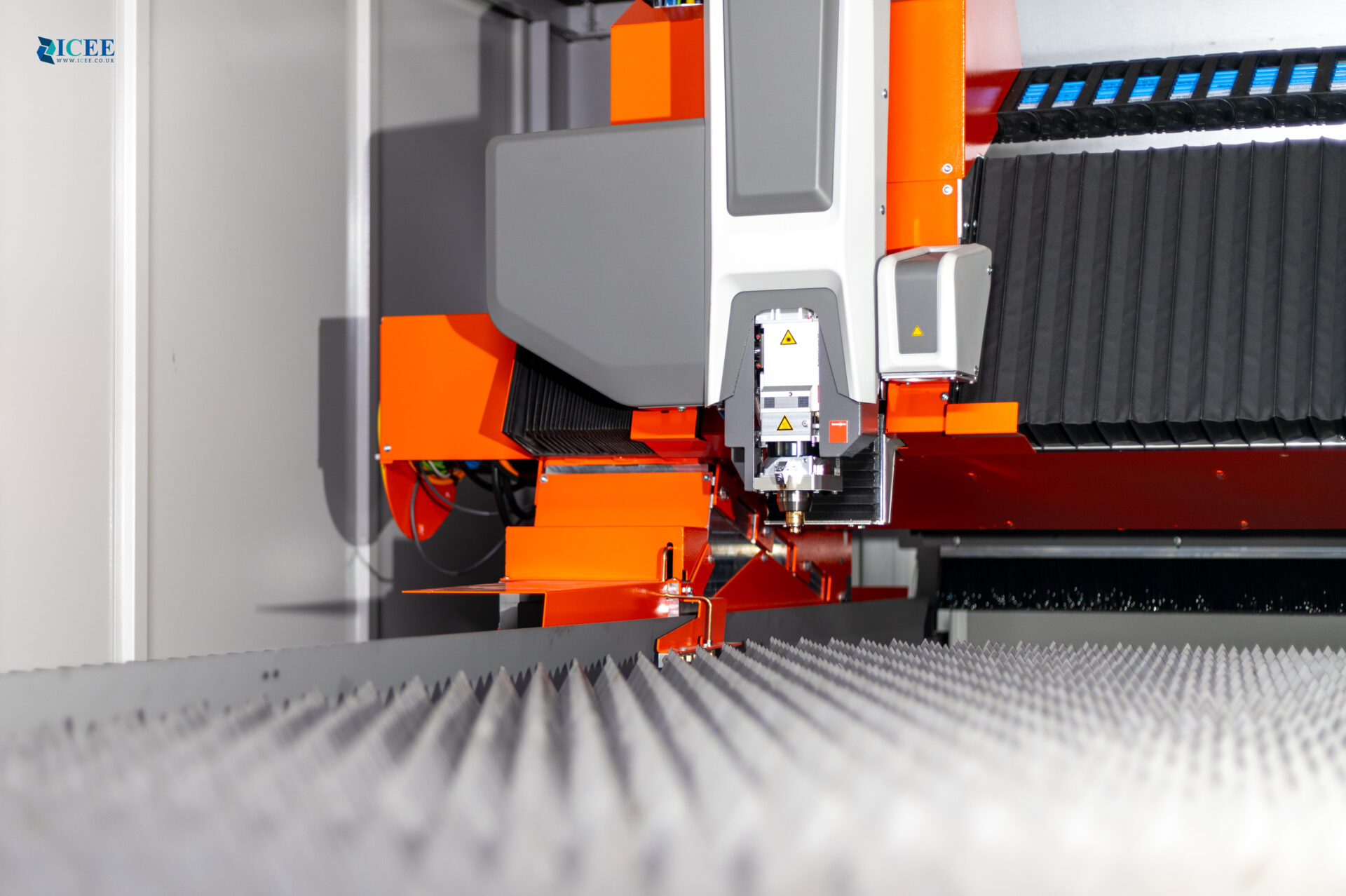

The Bystronic ByCut Star represents the pinnacle of innovation, boasting an array of remarkable features that include advanced process monitoring, tilt prevention mechanisms, and heightened precision controls. These capabilities not only enhance the quality of our end products but also streamline our production processes, ensuring greater efficiency and reliability. As a cornerstone of our turn-key manufacturing offering, our Fibre Laser Cutting service serves as the foundation for delivering precision-engineered sheet metal parts with unparalleled accuracy and speed. Whether it’s Stainless Steel, Copper, Aluminium, or Brass, our Fibre Laser is equipped to handle a diverse range of materials with ease, catering to the unique requirements of each project with finesse and expertise.

The integration of the Bystronic 6KW ByCut Star Fibre Laser into our operations marks a significant milestone in our journey towards enhancing customer satisfaction and driving business growth. By leveraging the advanced capabilities of this cutting-edge technology, we can offer our customers unparalleled precision, shorter lead times, and increased production capacity. With full manufacturing capabilities, complex geometric shapes, intricate designs, or large-scale production runs are made easy by the new machine, while ensuring consistent quality and reliability, meeting and exceeding the expectations of even the most advanced and prominent projects. This investment underscores our unwavering commitment to delivering value-added solutions that empower our customers to succeed in their endeavours. Moreover, it demonstrates our proactive approach to embracing innovation and staying ahead of the competition in an ever-evolving market landscape. By investing in the latest advancements in laser technology, we position ourselves as industry leaders, driving sustainable growth and cementing our reputation as a trusted partner for all manufacturing needs.

The new ByCut Fibre Laser can profile sheets measuring 3000 x 1500mm, with a max simultaneous positioning speed of 170 m/min. Automated manufacturing is made easy by our Bystronic ByTrans, which automatically loads batch sheet metal into the laser, while funnelling profiled parts back out, and placing them on a pallet ready to be stripped. With ICEE’s experience in a variety of industries, our Fibre Laser Cutting Service can be used for sectors such as Aerospace, Automotive, Defence, Telecommunications and more. Over the years, Fibre Laser Cutting has been a huge part of our business. Our Enclosure Manufacturing service is made easy by this advanced method of batch sheet metal cutting, helping to reduce lead times and cut down customer’s cost, while still being able to design and build completely bespoke to your requirements. To find out more about our Enclosure Manufacturing Service, please visit its dedicated page.

Terry Saunders, ICEE Workshops Leader, said; “The investment in this new Fibre Laser shows the long-term goals ICEE is looking to achieve, while offering our customers a faster, more streamlined cutting process. With the industries we work within constantly changing and developing, having the opportunity to consistently invest in modern machinery showcases ICEE’s unwavering dedication to offering customers the very best service”.