CNC punching machines offer unique advantages over other cutting and forming processes for sheet metal, from adding forms to punching multiple holes as a set pattern in a single hit. Often, manufacturers employ CNC punching machines in addition to laser, waterjet and other cutting machines to provide for increased flexibility, capability and productivity. Combination punch/laser machines also get the nod in many fabricating operations. The point here: CNC punching machines pack a powerful punch in the arsenals of successful sheet metal formers and fabricators.

And, like their cutting companions, CNC punching machines leverage rapidly evolving nesting software to produce parts quickly and accurately, while optimizing material utilization. For details on industry-wide CNC punching trends related to nesting, and a list of nesting tips for fabricators, MetalForming reached out to Gary C. Carnall, regional manager for Europe, the Middle East and Africa at Metamation, a Trumpf Group company specializing in sheet metal CAD/CAM software, with its U.S. core offices within Trumpf’s Chicago, IL, Smart Factory.

Different Punching-Machine Designs for Different Applications

“As opposed to laser cutting machines that don’t employ tools, tooling constrains nesting on CNC punching machines,” Carnall says, citing a disadvantage commonly attributed to CNC punching. On the other hand, he notes, some advantages chalked up to laser cutting over CNC punching can become disadvantages downstream. “For example, in theory, a part can be nested at any angle for laser cutting. But should that laser-cut part then require bending, a bend may crack the part due to unfavorable grain direction.”

So, grain direction then becomes a consideration in nesting for laser cutting and CNC punching.

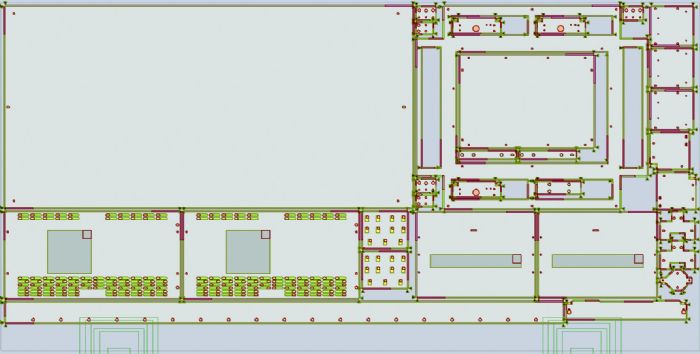

CNC punching machines take advantage of rapidly evolving nesting software to produce parts quickly and accurately, while optimizing material utilization. Such software also can perform smart-sort nesting to combine parts into nests that use similar tooling, eliminating the need for excessive tool and sheet changeout.

The particular style of CNC punching machines also affects nesting.

“Punches trace the outer profile of the part when making a square, for example,” Carnall says. “The type of punching machine determines how that’s done. Turret- and rail-style punching machines require different methods, and each serve particular niches very well.”

To this point, on a rail-style machine, a tool can rotate to any angle, Carnall explains, which provides flexibility in nesting and performance. A turret-style machine, with some exceptions, can’t do that, or has reduced functionality with perhaps a few tools that can rotate.

“Punching two 1⁄4-in. rectangles in a turret-style machine, for example, might require nesting one at a 0-deg. orientation, and the other at a 90-deg. orientation,” he says. “This eliminates some capacity and ability for material savings and speed.”

But again, each style of machine has a home.

“An OEM, for example, may not require a lot of tools,” Carnall says, due to a limited and more-uniform part portfolio. “A rail-style machine may be more beneficial here. Turret-style machines offer the possibility of more available tooling—a consideration for job shops.”

Combine Machine Management with Nesting Knowhow

For each machine style, machine management and nesting can bring significant gains in performance and overall equipment effectiveness (OEE). Machine management plays a crucial role, according to Carnall, as effective nesting means much more than just the number of parts placed on a sheet.

Machine management and nesting can bring significant gains in machine performance and OEE in CNC punching applications. Machine management plays a crucial role, as effective nesting means much more than just the number of parts placed on a sheet. Nesting according to available tools, for example, offers the opportunity for upped productivity.

“Some manufacturers will fill a sheet with 30 parts,” he explains, “but maybe they only needed 10 of those parts that day. The rest will become inventory or work in progress (WIP) that sits for a week until delivery or additional processing. Excess inventory becomes a substantial added cost.”

Combining nesting capability with proper machine management—scheduling, determining proper sheet size, etc.—adds efficiency to the overall production process.

An OEM-fabricator project provides a case in point, with Carnall and the Metamation team tackling challenges.

“By scanning more than a thousand parts produced by this fabricator on a turret punch press, we were able to determine tool usage,” Carnall recalls. “Using the data, we identified needed and unneeded tools. For example, suppose a fabricator must punch a 1-in.-square, a 0.75-in. square and a 0.50-in. square to nibble out the middle of a part to make an aperture. This does not require three different square punches, which eliminates the need for some tools. Doing so may require an extra hit or two, but it frees turret capacity to allow for other needed tools.

“By scanning and eliminating unneeded tools, we came up with a standard turret load,” he continues. “This allowed mixing of an optimal variety of parts when nesting, providing much higher material utilization as well as greater throughput. In this project, dynamic nesting combined with machine management reduced needed sheets from 130 sheets to 69 for the production run—a huge material savings as well as improved productivity. Nesting obviously played a big role, but proper machine management played a bigger role.”

Bottom line: Nesting software brings a lot, but be sure to look at the punching machine—how it runs, the tooling being used, etc.

Group Similar Parts

Along these lines, grouping similar parts and part jobs provides more gains, according to Carnall, who offers ways for this to be done using specific software capabilities as an example.

“The software accomplishes this in two core ways,” he says. “It may create what we call our nest job that includes the day’s requirements. When nesting, the nesting engine analyzes the required tools. If a scenario involves the need for more tools than the machine can provide in one go, it automatically splits the turret configuration. It groups as many parts as possible in turret configuration A, and then creates turret configuration B to nest the rest of the parts.

“Another method makes recommendations,” he continues. “When the software detects turret conflicts that require more tools than available turret space, the software tells the fabricator, ‘If you remove this tool and replace it with this other tool, I can mix these parts together in a nest.’ This method helps promote design to manufacture.”

At the end of the day, the approaches outlined above allow for completion of all needed jobs, though not necessarily one job at a time.

“This proves useful for job shops that have little control over what jobs are needed, and when,” Carnall says. “An OEM fabricator, on the other hand, may have more control and can work with its internal design department to optimize productivity and tool usage.”

More Nesting-Improvement Tips

Metamation provides additional tips for improving nesting on CNC punching machines, which Carnall expands on.

Where possible, try for a good mix of parts, but be mindful that pulling orders ahead of time could affect WIP.

“Job shops have less control than OEM operations as to the number and types of parts to be produced. A rule of thumb: The greater amount and types of parts you have to play with, the greater the ability for nesting software to increase material utilization. A demand list of 50 or 60 parts, as opposed to only four or five, creates a greater opportunity for high material utilization. A nesting engine will work from constraints, with the first constraint being the variety of parts.”

Try to limit the priorities placed on parts for production, as this allows a nesting engine to be more flexible in part arrangements.

“Excessive priorities handcuff a nesting engine. Constraints may be needed due to production schedules and secondary or other operations. Of course, fabricators don’t want to punch next week’s work today because that’s just WIP lying around the shop floor. But job shops may have more control than OEMs to mix in tomorrow’s work as needed.”Try to use adaptable tooling solutions. For example, the cutting process has few constraints other than material grain direction, whereas punching may have tooling constraints that limit the rotation of parts on a sheet.

“If the cropping tools in a turret punching machine only can function at 0- and 90-deg. orientation angles, then 0 and 90 deg. are the only available nesting orientations. But, using machine technology with auto-indexing enables tools to rotate their orientation. This provides more options for a nesting engine to provide greater material utilization. Avoid this on some materials such as aluminum, where bending on the grain will snap a part. But opportunities are there for improved nesting efficiencies on standard steels, for example.”

It’s better to stick with the largest possible sheet, but other standard sheet sizes, or even dual sheet sizes (large and small), can provide benefits in nesting.

“Some fabricators prefer to stick with a single sheet size, but allowing a nesting engine to select from multiple sheet sizes may improve material utilization. Automated sheet handling can help here, as increased material utilization must be weighed against additional time needed for sheet changeover.”

Review the process required for nesting. Some nesting software offers rapid nesting, but then requires the use of additional optimization programs. Others may be packed with different nesting styles and methods where finding the most optimal one may take more time, thus negating time and material-savings gains.

“Some software can nest parts and then require tooling setup afterward, which may not always work. Other software can provide nesting based on the available tooling. While the first option may offer increased material utilization, it only covers nesting geometry. Some fabricators can fall into a trap of seeing the increased material utilization, then prepare to load a sheet and realize that they can’t punch that nest because they don’t have the available tools.”