Refresh. Refill. Recycle.

Ball Aluminum Cups® Making a Difference

Ball Corporation’s ongoing commitment to sustainability has led to the introduction of the fully recyclable aluminum beverage cup. And as the world’s largest producer of aluminum beverage cans, Ball is dedicated to a concept it calls “Real Circularity” — making sure products get recycled, and are used again and again.

“We realize that there was a real opportunity to address the pollution problem and look at other areas that we could bring aluminum in to put a fully circular and fully recyclable product into consumers’ hands,” said Emily Fong Mitchell, President and General Manager of the Ball Aluminum Cup® Division. “So using the technology that we had in beverage can and bottle manufacturing, we were able to come up with an amazing aluminum cup. It gives an opportunity for more consumers to enjoy beverages, whether they’re having a draught pour or their favorite soda over ice. They can now have it in the world’s most sustainable material, which is aluminum.”

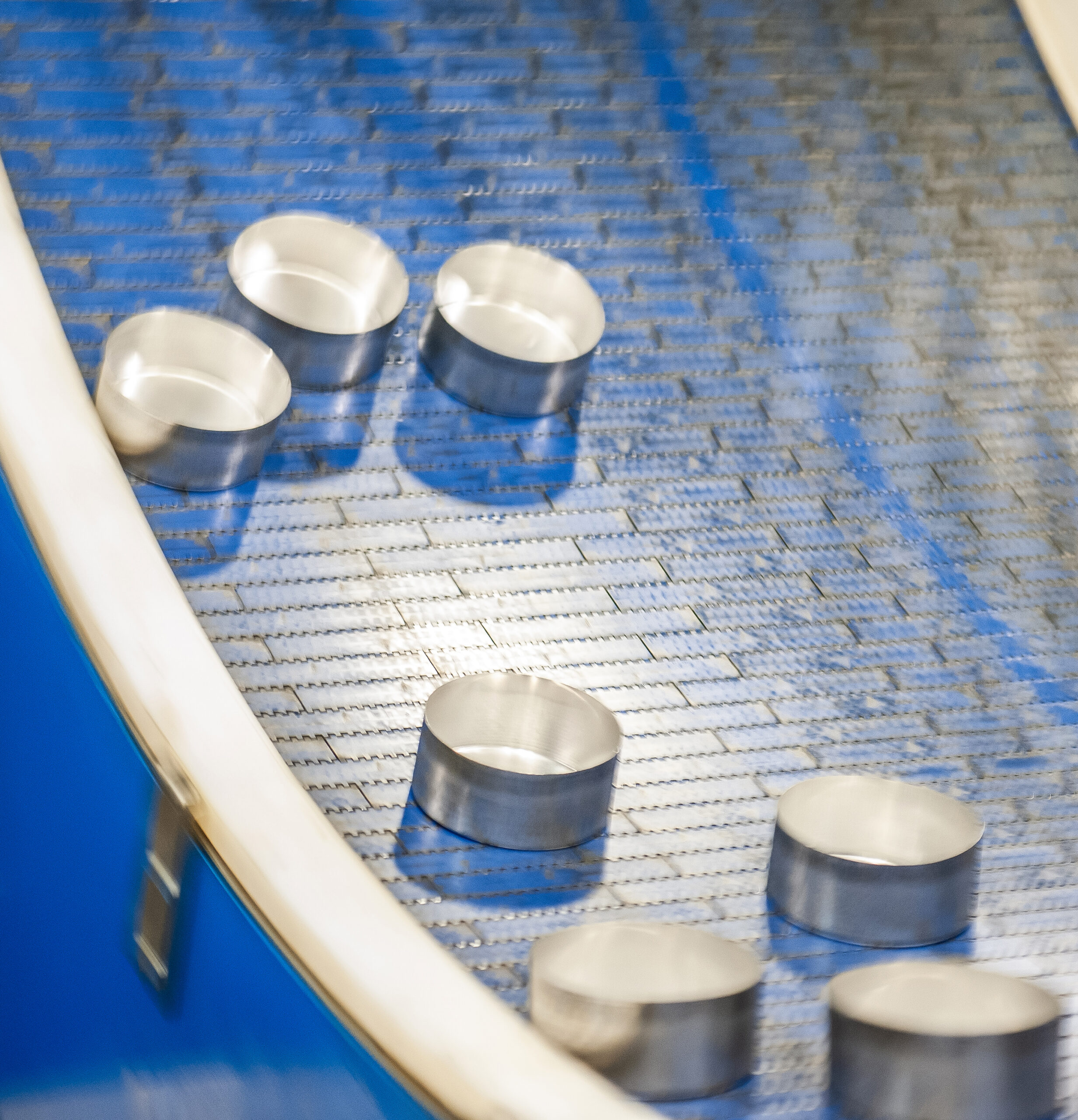

In 2020 Ball opened its dedicated aluminum cup manufacturing facility in Rome, Ga. The plant has grown to included two unique cupping lines, producing five different sizes of aluminum cups — 9, 12, 16, 20 and 24 ounces. Each line starts with a Nidec Minster DAC-H165 cupping press.

“When Ball decided to make the aluminum cup, we elected to partner with Minster as an innovative machine builder to help with this innovative product we are taking to market,” said Zach Dixon, the Engineering Manager at the Ball Aluminum Cup® plant. “The Minster presses are the first process in line to help us deliver our sustainable product to end consumers.”

The dynamic balancing system incorporated into the design of the DAC-H165 allows for higher run speeds,while eliminating unbalanced forces for optimal quality and uptime.

“With the Minster DAC-H165, two of the key features we really like are the magnetic base and the quick lift system that helps us get our asset changes down to two to three hours, when in the past, it’s taken up to four to five hours,” Dixon added.

Today, Ball Corporation is the largest end user of Minster presses in the global container market. Ball and Minster have a trusted relationship that goes back to the 1970’s.

“It’s special to have such a long term partnership,” Dixon said, “because we know Minster is just a phone call away to get the support we need, and it’s been that way for more than 50 years.”

Since each aluminum cup is made up of more than 90 percent of recycled material, Ball dedicates resources to maintaining a flow of recycled aluminum.

“And the reason that’s so important is because it takes 95 percent less energy to recycle aluminum than it does to create prime aluminum,” Mitchell said. “So as we think about our carbon footprint as well, it’s really, important to recycle. That’s why Ball has a very active sustainability and recycling team. We are working, not only to lobby and educate different communities, but also making sure that we’re building the awareness and the education amongst the end consumer.”

Unlike plastic, aluminum recycles over and over without losing quality, and it has been estimated that 75 percent of all the aluminum that was ever produced is still in use today.

“So it’s truly a circular material, especially when we can we look at other substrates and compare it in that way,” Mitchell added. “The other thing with our cup is you can just put it into your normal recycling stream the way you would with your soda can or your beer can, and it can actually go back into the stream, be recycled, and come back as a new cup or a new can in just 60 days.”

Director of Sales Operations for the Ball Aluminum Cup® Division, Kari Dukai said the product is available in more than 35,000 retail outlets around the country.

“You can find our cups on your store shelves and a lot of on-premise locations,” Dukai said. “So think about your sports stadiums, your music venues, concert halls, conference centers, hotels, you name it. We’re in there. And if we want people to be able to fully replace their plastic cups, we know we need to make everything from the 9 ounce wine and cocktail size up to the 24 ounce soda and draught beer cup.”

The turnkey production system at the Ball cup plant also includes a state-of-the-art seven-color printing process providing unique options for decorating the cups.

“Not only is the Ball Aluminum Cup® fully recyclable and a really premium beverage experience, but what we really love about it is the ability to fully customize it,” Mitchell said. “You can have a 360 degree marketing message on it. So whether that’s your sports team, whether that’s a corporation, whether that’s your restaurant, you have a real ability for more branding and more marketing.

And what we’ve found, especially at our arenas or our stadiums and some of our big restaurants, is that consumers love these cups so much, they take them home,” she continued. “And then your branding goes with the consumer.”

And Ball officials also tout what they call a ‘premium drinking experience.’

“So when you’re going down that aisle at your favorite supermarket, amongst a sea of poly bags and plastic, you see this cardboard box of aluminum cups, which really stands out,” Mitchell said. “You don’t want to put your drink in a flimsy, disposable cup. You want this great experience of feeling really cool to the touch. You see that little frost on the edges of the of the cup and it’s just wonderful.

“People say, ‘wow, what is this thing? This is really cool. Where did you get this?’ And we’re seeing our consumers become ambassadors for this product because it really is different,” she continued. “It really shows that you care about the environment and that you’re making an impact to the planet.”

Dukai said the market for aluminum cup continues to expand as Ball begins taking the product to global consumers.

“Every day is a new challenge and every day is an opportunity,” Dukai said. “We’ve been producing these cups for just a short amount of time, and earlier this year we surpassed 100 million cups sold in the market. And for me, knowing that we have taken 100 million plastic cups out of the oceans and landfills is what’s keeping me going. “