For any machine application, meeting the required design specifications and ensuring component reliability is crucial, and there are few sectors with more exacting requirements than the defence sector. Any unpredictable behaviour in springs and pressings will lead to catastrophic consequences, especially within military applications.

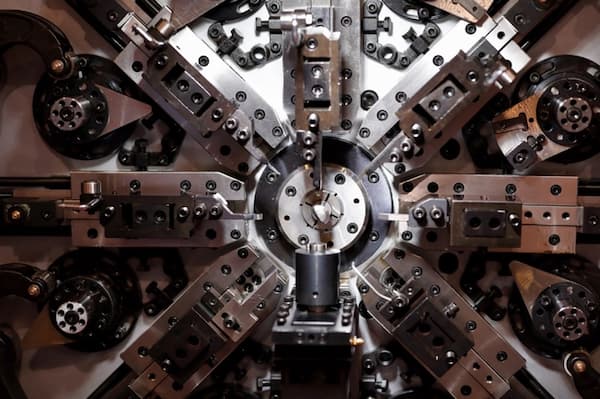

This is why, at European Springs, we employ precise manufacturing processes, utilising industry-leading machinery. Our stringent approach guarantees springs and pressings that align with defence requirements, ensuring consistent performance and longevity. Read on to learn more about military-grade springs and pressings.

SPRINGS IN GROUND DEFENCE

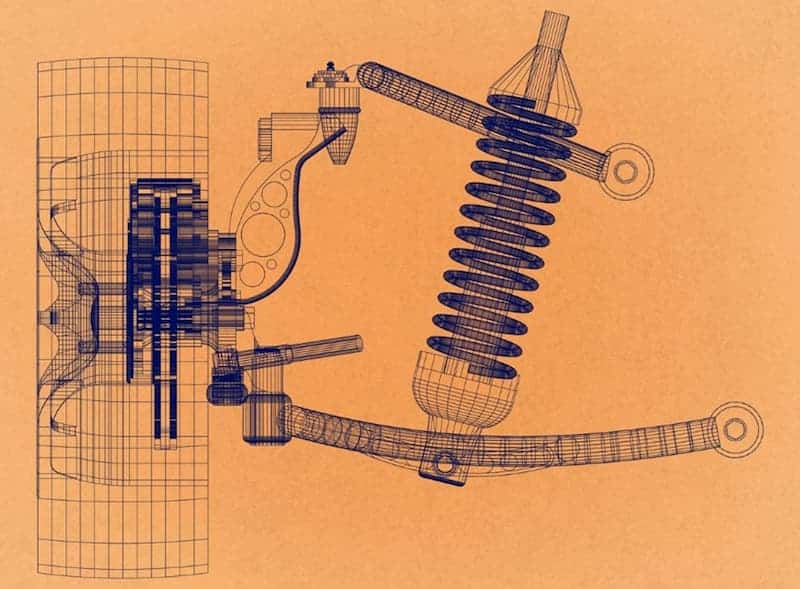

Springs are vital components in various ground defence systems as their inclusion in designs significantly improves mobility and performance in a variety of challenging scenarios. For example, you’ll find a broad range from torsion to compression springs used in propulsion systems within armoured vehicles, tanks, and other defence-oriented vehicles.

Another example is suspension systems; our springs manage impacts from uneven terrain and provide optimal comfort for troops operating armoured vehicles. Skilfully designed by our expert team and manufactured to withstand heavy loads and rigorous use, our springs ensure that ground defence vehicles maintain maximum responsiveness, even in the harshest environments.

Additionally, springs are indispensable to firearms and artillery mechanisms, like recoil systems. They assist in dissipating energy when a weapon is fired, contributing to better accuracy, longevity, and safety.

SPRINGS IN AIR DEFENCE

Our spring design team’s expertise also extends to the aerospace sector, where close tolerances and high-performance materials are essential. Springs play a significant role in numerous aerospace applications, including the safety, longevity, and performance of aircraft.

One example is constant-torque springs, which are used in military aircraft. As part of the complex mechanisms in military machines, these springs play a significant role. One of their primary functions in military aircraft is within the seating mechanisms.

Military drones, which are a specific type of military aircraft, use an array of spring designs to ensure their proper functioning. This includes the drone’s need to withstand high speeds, extreme temperatures, and vibrations.

Additionally, various spring designs, such as parachutes and ejection seats, are integral to safety equipment. Being critical life-saving devices, their dependability and robustness are indispensable, and our springs are designed to deliver consistent performance for their entire lifecycle.

SPRINGS IN SEA DEFENCE

Similarly, springs serve crucial functions in naval defence applications as they contribute to powerful propulsion systems that demand durability and efficacy. They also contribute to the manufacturing of sophisticated weaponry used by naval vessels, from gunfire control systems to missile launchers.

While it’s challenging to pinpoint a single most commonly used spring design in military and marine applications due to their vast and varying needs, compression, extension, and torsion springs are standard components found in many naval equipment and devices.

As for the material, the materials used for springs in such high-stress conditions need to be robust, corrosion-resistant, and durable. Therefore, the most commonly used materials are often variants of high-strength steel alloys, as they will frequently need to withstand water, salt, and extremes of temperature and pressure. Other construction materials might include certain heavy-duty, corrosion-resistant polymers, which have been found to be safe and strong for many military applications.

POSITION OF PRESSINGS AND WIREFORMS IN DEFENCE

As you can see, whilst it’s common to find springs throughout defence sector applications, you’ll often find general wire forms and pressings within those applications also. These fine-tuned components drive efficiency across ground, air, and sea defence systems. Here are some examples of their use.

PRESSINGS APPLICATIONS

Pressings deliver reliability and durability. They are used in applications in radio communication equipment, assisting in signal transmission. In vehicle armour, precise pressings improve reinforcement. They adhere to strict manufacturing standards, ensuring consistency and performance in high-stress environments.

WIREFORMS APPLICATIONS

Wire forms, tailored to the task, provide flexibility, strength, and resilience. In aerospace control systems, they ensure seamless operations. Wire forms contribute to vehicle suspension mechanisms, aiding in off-road mobility. Crafted meticulously, they meet the stringent demands of the defence industry, reinforcing reliability in all applications.

INSIGHTS FROM DSEI 2023

Defence & Security Equipment International (DSEI) represents a prominent global stage for defence and security professionals. This event showcases cutting-edge advancements, facilitates collaboration, and fosters invaluable networks across the industry.

This year’s gathering proved to be particularly impactful, framing significant global defence and security discussions under the theme “Achieving the Integrated Force”. This event showcased the future of defence, with an emphasis on collaboration, innovation, and integration across many industries, including manufacturing.

Members of our group regularly attend DSEI, and we regard it as an optimum opportunity to reveal our innovative developments and demonstrate our steadfast commitment to advancing the defence sector.

Attending DSEI presents several undeniable benefits. By engaging in discussions and exploring the latest technologies, we broaden our knowledge and hone our edge. Collaboration with partners and clients ensures constant evolution in our manufacturing processes, maintaining a high level of excellence.

By attending this event, we bring awareness to our position as industry leaders to clients and share our dedication to delivering outstanding solutions in the defence and security sectors.