C&C Fabrications provides a one-stop-shop for metal fabrication projects. Collaborating with customers to get projects completed to their specifications.

C&C share five key steps to successfully partnering with metal fabrication companies

- How should I share my ideas for a metal fabrication project?

Not all challenges are the same, whether it is budget constraints or specific composition of the metal, choose a company that takes the time to listen to your requirement and understand exactly how the end-product must operate, to maximise your efficiency and create the perfect, bespoke steel solution.

At C&C, its teams work in collaboration with clients, with feedback opportunities at each step of the process to make sure the crafted product is right first time.

Through this process, the end product may not be the original idea but instead a product of our collaborative consultation process that matches the company specs. C&C recently collaborated with a customer on an office refurbishment project in York, where it was approached C&C with an idea by the customer which C&C converted into the end product they needed.

2. How should a metal fabrication project be designed?

Steel fabricators should work alongside clients to design the end product, even from the initial stages of design development. Having a thorough and complete design brief ensures an efficient and cost-effective fabrication process. Not only does this save time, but can also mitigate against costly mistakes down the line.

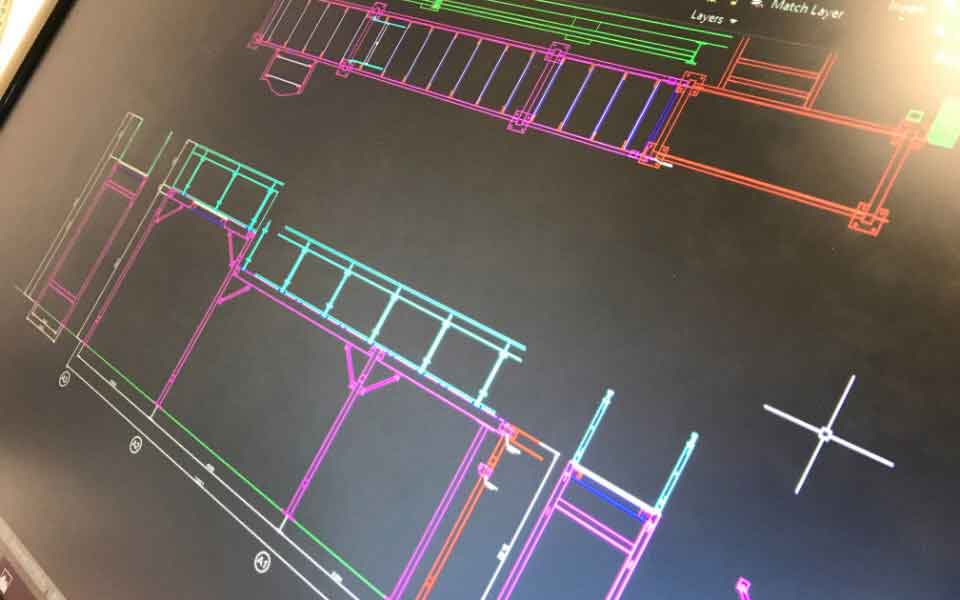

C&C can produce detailed, 3D modelling designs using the company CAD software, so can see the project being brought to life.

C&C team are always looking to maximise their efficiencies throughout the end-to-end process, thus prioritising collaboration and direct contact throughout, keeping clients in the loop at every step. C&C produce detailed, 3D modelling designs using CAD software, so clients can see the project being brought to life so that mocked-up designs match exactly what clients need from the outset.

3. How does metal fabrication manufacturing work?

Manufacturing processes in metal fabrication, like punching and welding, are vital to produce the exact solution you require. Choosing experienced, end-to-end steel fabricators is key.

At C&C the company have the latest laser cutting and powder coating technology to incorporate into our one-stop shop of punching, bending, welding and assembly services. Using our 6KW Kimla laser and providing the end-to-end process, C&C can manufacture to the highest standards, exactly to customer specifications, providing the security and confidence that the end-product will be long-lasting and durable for the customer needs.

One-stop shop steel fabricators like C&C are the efficient choice. British manufactured in Yorkshire, providing quality metal fabrication solutions for your business.

4. What should a metal fabrication provider deliver?

Completing thorough consultation, design and manufacturing stages of the process means your solution is produced to your exact specifications, efficiently and cost-effectively. This creates fewer issues with installing and using your end product. From concept to completion, your provider should deliver steel fabrication solutions that meet your deadlines, your budget, and your standards.

Chris Taylor, Director of Finance and Operations for C&C says: “We keep our customers informed at every stage of the process and always meet a deadline we’ve committed to. A lot of our customers are repeat customers who keep coming back to us with projects. This is a reflection of the level of service and quality of products we produce using our thorough, one-stop shop service.”

5. What is the level of service I should expect in metal fabrication?

The level of service you receive from your steel fabrication partners is vital. Efficiency and cost-effectiveness are key elements to consider when choosing your steel fabrication service provider and choosing a one-stop shop is the optimal choice.